Bopp Feather Feel Thermal films

Bopp Feather Feel Thermal films Specification

- Tensile Strength

- Strong

- Thickness

- 24 Micron - 42 Micron

- Surface Handling

- Glossy/Matte

- Length

- 4000 Meter

- Width

- 300 mm - 1600 mm

- Feature

- Feather Feel, Excellent Bonding, High Transparency

- Material

- BOPP (Biaxially Oriented Polypropylene)

- Processing Type

- Thermal

- Hardness

- Soft

- Transparency

- High Transparency

- Color

- Clear

- Roll Diameter

- 76 mm (Standard Core)

- Print Compatibility

- Offset/Inkjet/Digital printing

- Shelf Life

- 12 months

- Usage

- Lamination of brochures, covers, packaging, and print enhancement

- Adhesive Type

- Low melt, extrusion coated

- Heat Activation Temperature

- 90°C - 110°C

- Pack Type

- Roll

- Moisture Resistance

- Excellent

About Bopp Feather Feel Thermal films

BOPP - THERMAL BASE FEATHER FEEL

Excellent Feather feel finish, excellent resistance to scuff, scratch and tear. BOPP thermal is ready product to laminate by thermal lamination.

TDS: This is available in 23, 36 & 50 microns.

This film can be used for following applications:

- It is substrate for extrusion coating by applying chemical during process of extrusion coating at customer end.

BOPP - GLOSS

It has 3 thickness variants ( 20, 22, 24 microns ) and has good bond & better optics.

TDS: This is available in 20, 22 & 24 microns.

This film can be used for following applications:

- Book covers.

- Magazines.

- Posters.

- Catalogues.

- Sweet boxes, cartons.

- Visiting cards.

BOPP - MATTE

This is available in 3 microns ( 20,22,27 ). It has good matte finishing with high yields and is suitable for UV Spoat coating.

TDS: This is available in 20, 22 & 27 microns.

This film can be used for following applications:

- Dairy.

- Brochures.

- Tags, shopping bags.

- Magazines.

- Posters, visiting cards.

BOPP - FEATHER FEEL

This is available in 2 microns ( 32,38 ). It has feather feel finish.

TDS: This is available in 32, 38 microns.

This film can be used for following applications:

- High value graphic designs.

- Posters.

- Magazines.

- Brochures.

Premium Print Enhancement

BOPP Feather Feel Thermal Films elevate the quality of printed materials through superior bonding and high transparency. Their feather-like texture provides both an elegant aesthetic and tactile experience, making them an ideal choice for projects requiring visual impact and a professional finish.

Reliable Performance and Compatibility

Designed for versatility, these films support multiple print methods including offset, inkjet, and digital. They offer dependable adhesion at low melt temperatures, ensuring consistent results while maintaining the integrity of the underlying media. Their strong tensile strength makes them suitable for heavy-duty packaging as well as delicate covers.

FAQs of Bopp Feather Feel Thermal films:

Q: How do I apply BOPP Feather Feel Thermal Films for lamination?

A: To laminate with BOPP Feather Feel Thermal Films, use a thermal laminating machine set between 90C and 110C. Ensure the printed material is clean and dry. Feed the film with the standard 76 mm core into the machine, aligning it with the substrate for a seamless application. The low melt adhesive bonds quickly, providing a smooth finish.Q: What types of printing are compatible with these films?

A: These thermal films are designed to be compatible with offset, inkjet, and digital printing. Their high transparency and excellent bonding properties ensure that prints retain clarity and vibrancy post-lamination, making them versatile for various professional printing applications.Q: Where can I use BOPP Feather Feel Thermal Films effectively?

A: You can use these films for laminating brochures, book covers, packaging materials, and other printed products requiring enhanced durability and a refined finish. Their strong structural properties and moisture resistance make them suitable for both commercial and premium consumer applications.Q: When is it best to use the Feather Feel feature?

A: Utilize the Feather Feel feature when you want to elevate the tactile and visual appeal of your project. Its ideal for presentations, high-end brochures, and luxury packaging where customer experience and product differentiation matter most.Q: What benefits do BOPP Feather Feel Thermal Films provide?

A: These films offer strong tensile strength for durability, high transparency for vivid print visibility, and excellent bonding for long-lasting protection. With moisture resistance and a distinctive soft touch, they ensure your printed materials look and feel premium while being well-protected.Q: How long is the shelf life of these thermal films, and how should they be stored?

A: BOPP Feather Feel Thermal Films have a shelf life of 12 months. Store them in a cool, dry place away from direct sunlight and humidity to maintain optimal performance and adhesive properties throughout the storage period.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thermal Lamination Products Category

Packaging Film

Minimum Order Quantity : 100 Rolls

Material : PP

Color : Transparent

Feature : Other, Moisture Proof, Durable, Tear Resistant

Width : Customizable

Hardness : Rigid

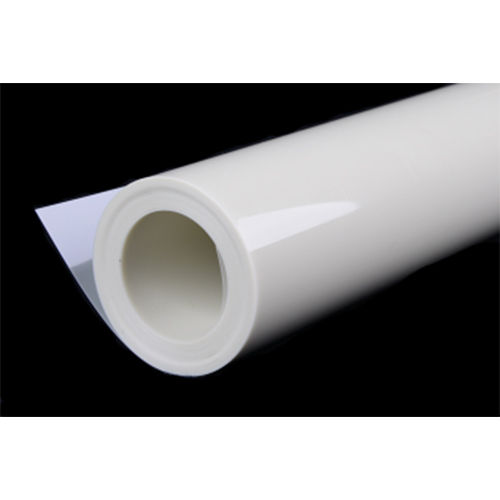

Garware Milky Polyester Film Em6

Minimum Order Quantity : 50 Kilograms

Material : Other , Highquality polyester

Color : Milky white

Feature : Other, Milky, opaque film for enhanced privacy and light diffusion

Width : Customizable, available in various widths

Hardness : Other, Flexible

Thermal Lamination

Minimum Order Quantity : 50 Kilograms

Material : BOPP

Feature : Waterproof, Moisture Proof

Width : 380 1500 Millimeter (mm)

Hardness : Rigid

Sipet Liner (Off-line) Sheet

Material : PET

Color : Clear

Feature : Other, Durable, Tear Resistant

Width : 1 Meter

Hardness : Rigid

Request A Quote

Request A Quote Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS